INDUSTRIAL SOLUTIONS

Listen beyond the noise

Almost every industrial facility has various forms of monitoring equipment in place to avoid down-time and be able to maintain consistent production. But what about the failure and the deviation-trends that are only indicated by sound? Up until now, human hearing has been an important part of maintaining industry facilities. Experienced employees will be able to listen to the sound from the facility and tell when something is wrong. At the same time, there is an individual bias when using human experience, depending on the individual itself, whether it is before or after lunch, and how much they have slept the night before. In addition, industrial facilities are often noisy, which makes it difficult to hear when something is off in the sound environment, or something is deviating over time.

Adding automatic sound measurement sensors to your condition monitoring and quality control procedures, removes this individual bias and prevents exposing humans to possible hazardous and noisy environments. This digitalization of the human experience fills a gap in the existing, common monitoring systems, removing any possible holes in the maintenance fence, ensures up-time, and enables a more sustainable production.

Enhance quality control and production uptime with our sound measurement sensors and machine learning models. Detecting faults beyond the noise and automating procedures, ensures continuous production and reduces product waste. Digitalize human experience in hazardous environments.

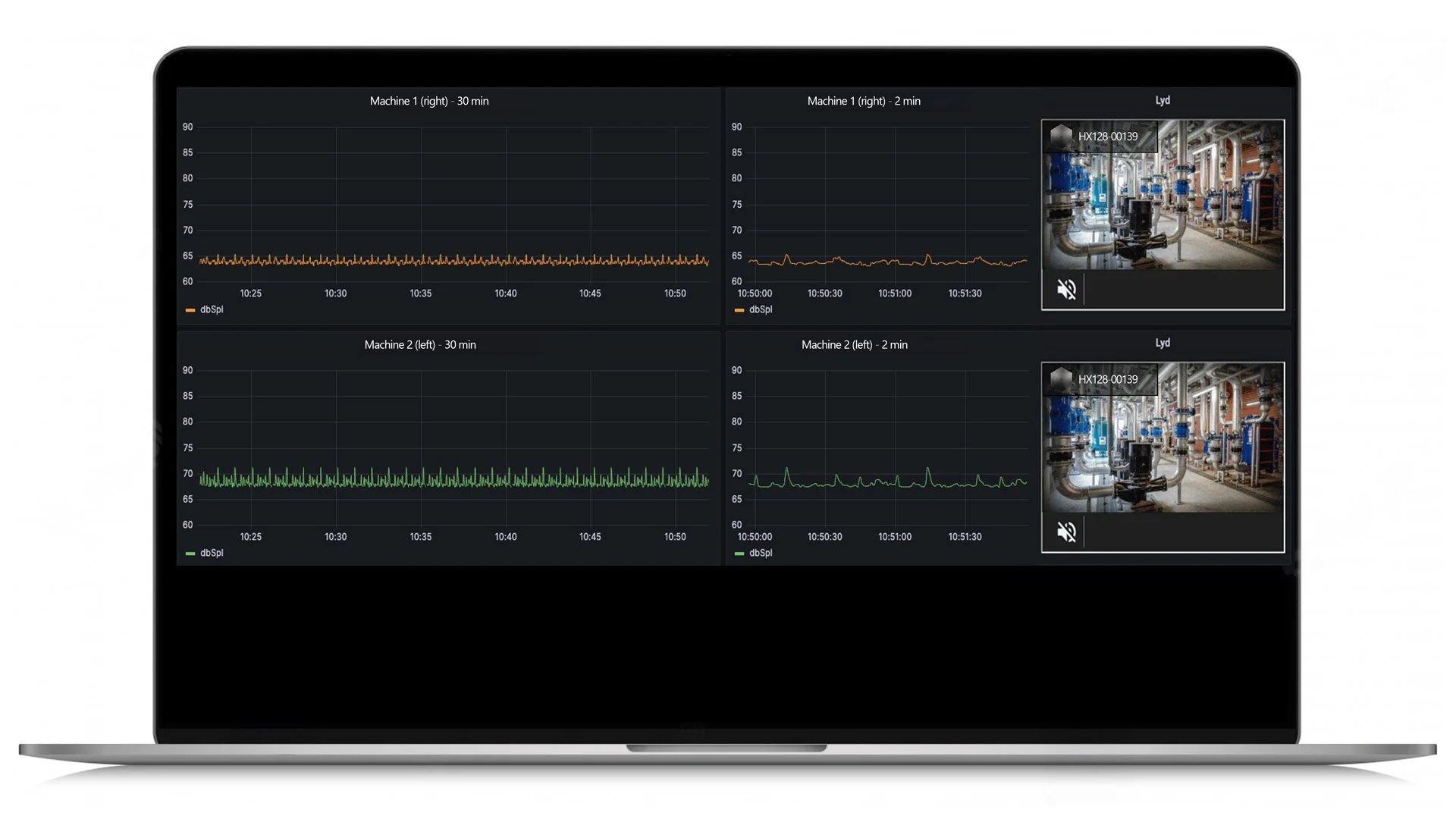

Optimize production and maintenance with our acoustic sensors. Listen for trends, deviations and anomalies in machinery and processes. Swift visual identification, remote monitoring and predictive maintenance, adds value to industrial processes, and helps ensure increased uptime.

Try our industrial array simulator, illustrating the functionality and benefits of a microphone array in an industrial environment. Swap between the array and the microphone, and drag the beam around to hear the different deviations in the facility.

THE PRODUCT

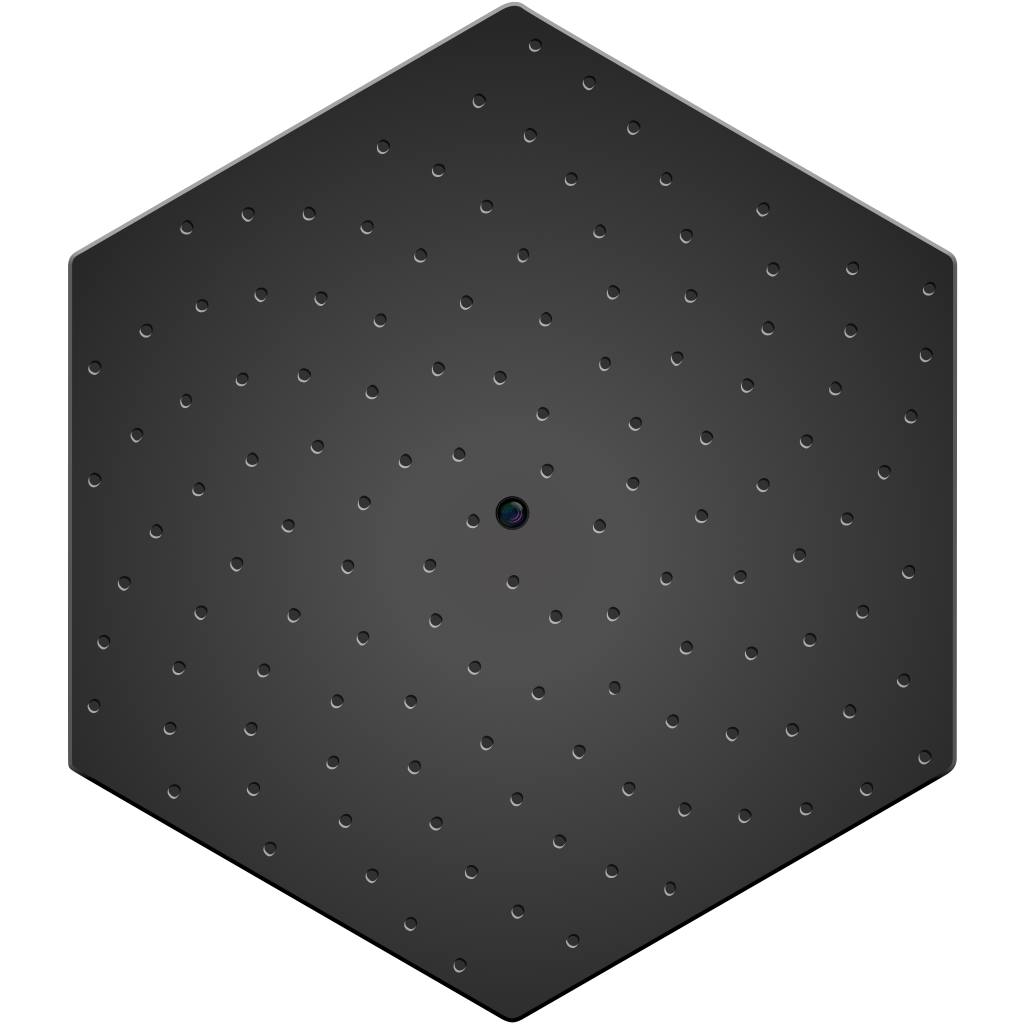

HX128

The HX128 sensor is a passive microphone array consisting of 128 microphones and an optical camera for both “superhearing”, visualization of sound sources and remote sound measurement and monitoring. The audio is captured by the microphones and analyzed on-edge by the built-in signal-processing unit (SPU). The HX128 is built for extreme and harsh industrial environments and can operate in a wide range of temperatures and conditions.

FEATURES

Remote monitoring

Automatic detection

Rich and flexible API

Multiple listening points from the same array

Custom algorithms looking for specific sound signatures

Passive

SPECS AT A GLANCE

Material: Aluminum

Storage: 120 GB SSD

Dimensions: 415x54x475mm (16.3x2.1x18.7in)

Operating temperature range: -20°C to 70°C

Communication standard: OPC-UA